UltraSlim Linear Brake

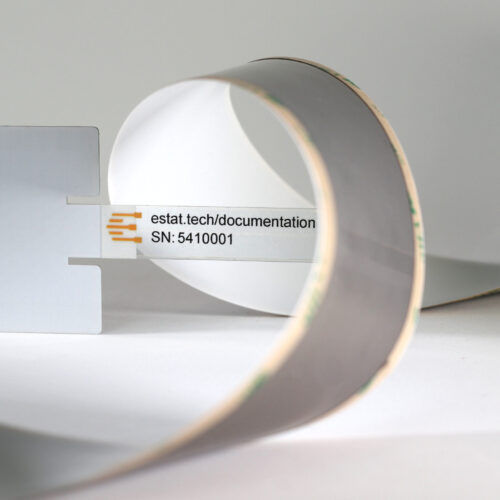

ESTAT’s UltraSlim Brakes are the world’s thinnest brakes. They are truly paper thin. The entire brake is .015″ (0.4 mm) thick and is installed with a simple and innovative “peel and stick” approach. This makes them uniquely well suited to compact assemblies and retrofitting brakes into existing systems.

If you can fit two pieces of paper, you can fit an UltraSlim brake!

ESTAT Brakes enable the safe use of linear motors in a vertical configuration without adding significant mass to the moving elements.

Download our white paper to learn how to effortlessly pair your ESTAT brakes with motion control products such as SCHNEEBERGER’s Absolute Measuring System (AMS) and servo drives from Copley Controls.

Description

Overview

ESTAT’s UltraSlim brakes fit in spaces no other brake can. They enable accurate position holding, emergency braking and motor support for static tasks. Replace your linear profile clamps, rail brakes or rod locks with this unique compact system. Like all of ESTAT’s products, these brakes are electroadhesive. Meaning they hold when powered on and release when powered off. We also have a power-off engage model available.

Design Considerations

The UltraSlim linear brake can support 1 N/cm² of overlap area between the stator and the mover. The brake can be made of one overlapping area or multiple.

The UltraSlim linear brake allows users to install a brake into an ex isting assembly with little to no redesign. The only requirements are:

1) There is sufficient area between the mover and the stator to support the desired load. The static holding force of the linear brake can be estimated as 1 N/cm² of active overlap area. (note there are 2 mm of insulating edge on the perimeter of each electrode that do not count towards this area.

2) The gap between the mover and the stator in which the brake is installed is within tolerance: 0.016-0.020 inches. ESTAT can assist with filling larger gaps.

As an example, consider the stage driven by a linear motor shown to the right. If the space between the rails under the stage is 10 cm by 20 cm (3.9 x 7.8 inches), a brake mounted to these surfaces would enable 120 N (26 lb) of holding force.

The UltraSlim linear brake is composed of moving and stationary electrostatic webs that can be configured in two ways:

Wireless mover: This configuration requires no electrical connection to the mover.

Wired mover: In this configuration an electrical connection to the mover is used. This option is lower cost compared to the wireless option.

Device Operation

1) ESTAT’s brake controllers enable simple integration of the UltraSlim brake. Simply connect the brake controller to a digital signal (3.3-24.5V) to engage and disengage.

2) ESTAT brakes arrive with pressure sensitive adhesives pre applied. If you have applied a screen protector or decal, you know how to apply ESTAT brakes. Our tools and step by step instructions make it easy.

3) ESTAT’s UltraSlim Linear Brakes are best suited to holding brake applications. This means that the load should be brought to a complete stop before engaging the brake and the brake should be disengaged prior to moving the load. This will ensure the longest life of your brakes.

Keywords:

linear actuators, Electric Glue, electric clamp, pneumatic clamp, linear motion systems, Rail brake, Electroadhesion, planar motors, Linear brake, electrostatic brake, electroadhesive clutch, Rod brake, pneumatic linear brake