Description

Overview

The thinnest rotary clutch ever. Our line of UltraSlim Rotary Clutches provide the same holding torque as conventional options with 10x less mass, 10x less volume, and 1000x less power consumption.

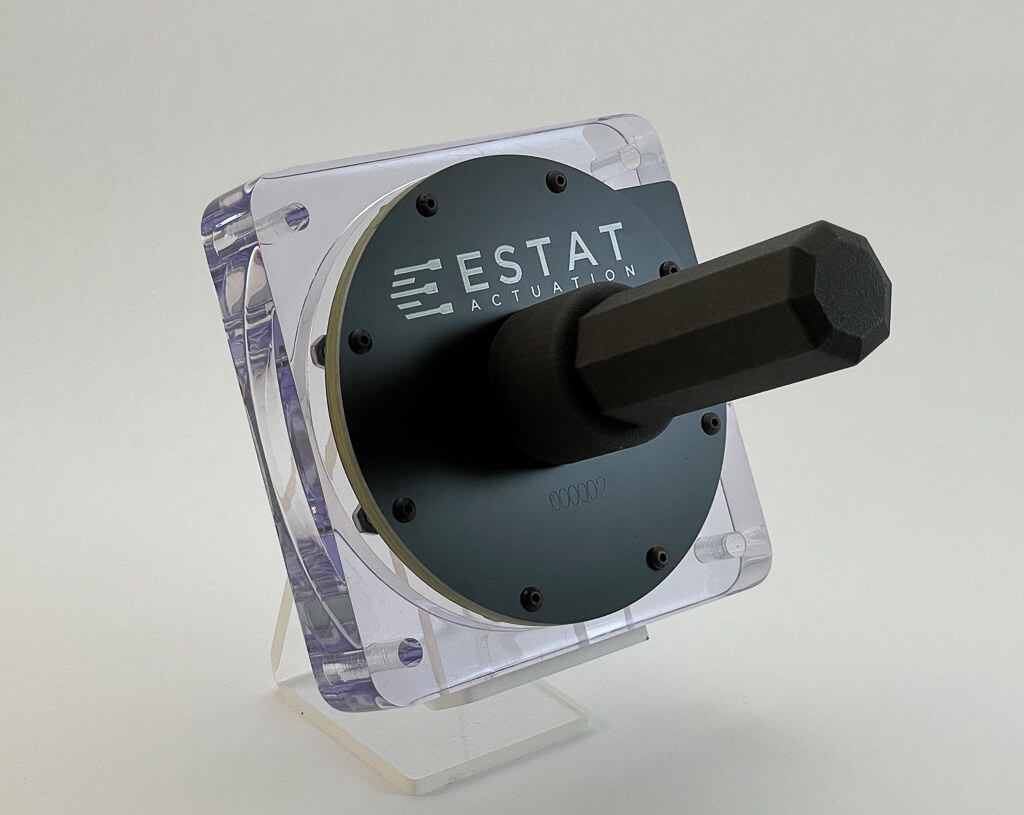

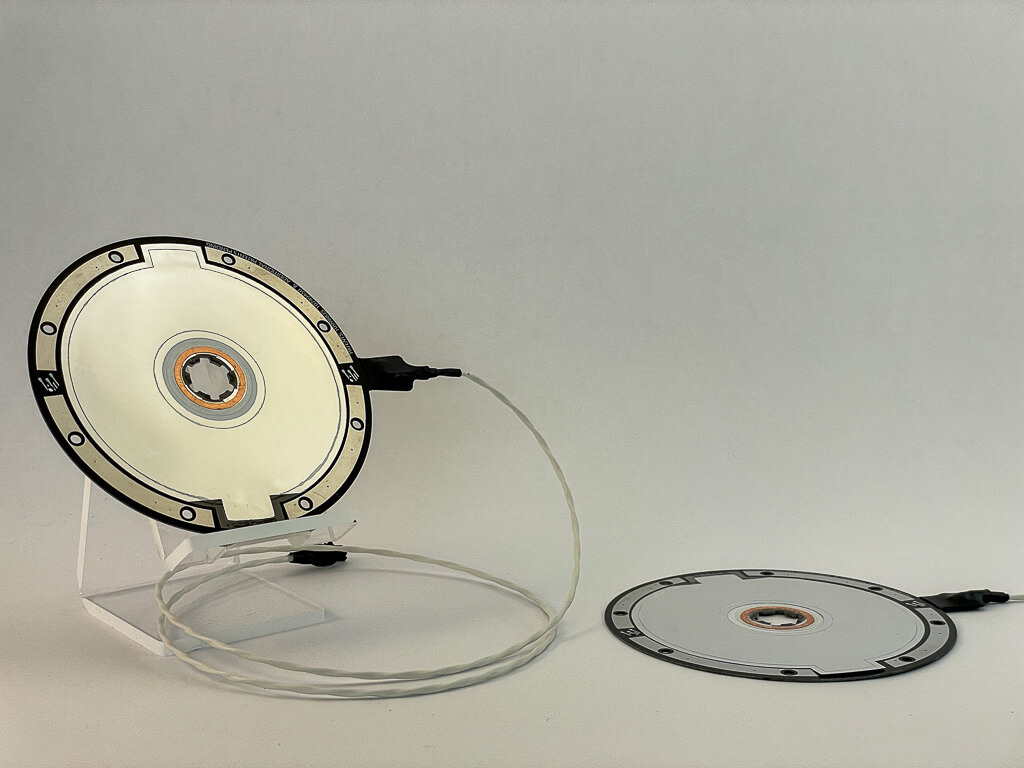

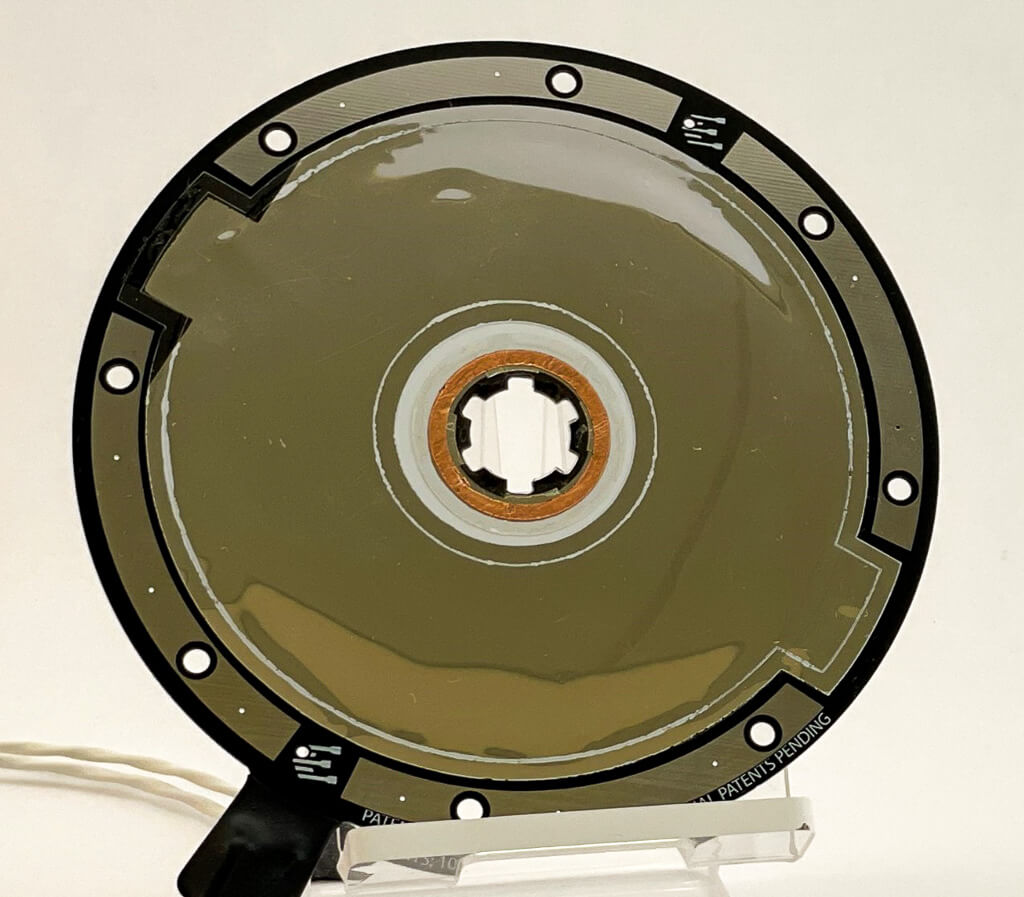

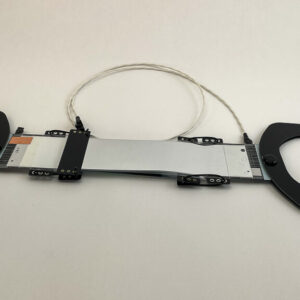

The UltraSlim Rotary Clutch is available in a number of thicknesses to achieve different target holding torques. All of the clutches are composed of clutch modules. Individual clutch modules stack together to make a rotary clutch unit. Each clutch module adds 4 Nm of holding capacity and approximately 1.2 mm of thickness. Starting on the low end, the US-4 is demo unit that represents a single clutch module without any additional components. Then moving up in rated torque, the US-12, US-24, and US-36 are full clutch units capable of 12 Nm, 24 Nm, and 36 Nm of torque. Respectively, they are composed of approximately 3, 6, and 9 clutch modules. Clutch units ship with a base and handle for instant evaluation after unboxing.

Device Operation

ESTAT clutches are load-bearing capacitors. Applying voltage across the clutch electrodes causes accumulation of positive charges on one side of the clutch and negative charges on the other. This results in adhesion between the rotor and the flexible electrodes, which locks the clutch. As capacitors, ESTAT clutches require minimal maintenance current to remain engaged (< 10 µA). The clutch disengages when the voltage potential is removed. The inner clutch rotor interacts with a spline shaft. The outer clutch electrodes are connected to the clutch housing. See the cross-section diagram below for a visual comparison of the Disengaged (Power Off) and Engaged (Power On) states of an ESTAT rotary clutch.

Key Features

- Lightweight: At about 30 grams per module, ESTAT rotary clutches are the lightest clutches ever built.

- Thin & Compact: Being just over 1 mm thick, ESTAT rotary clutches can fit almost anywhere.

- Efficient: All ESTAT rotary clutches consume less than 1 mW of power while activated.

- Modular: Easily add clutch modules to increase rated torque, or remove clutch modules to reduce rated torque and save space.

- Tunable: Targeting a precise slip torque? No problem. Our clutches’ torque scales with input voltage; dial in a particular input voltage to achieve a particular slip torque.

- Safe: Containing no dangerous moving parts and drawing only microamps to milliamps of current, ESTAT clutches are much safer to handle than electromagnetic alternatives.

Primary Applications

- OEMs → unlock greater performance by reducing weight and power consumption

- Integrators → save your customers money by improving efficiency system-wide

- AGVs/AMRs → get more done with less space; more productivity with each charge

- Cobots → optimize your joints, maximize your payload, and enhance human safety

Custom Requests

Does your application demand a torque not listed here? Need a custom outer diameter to fit in your actuator stack? Prefer a specific shaft geometry? Please reach out to us at [email protected]. Our designs our highly customizable, and we’re eager to create an actuation solution to fit your exact requests.